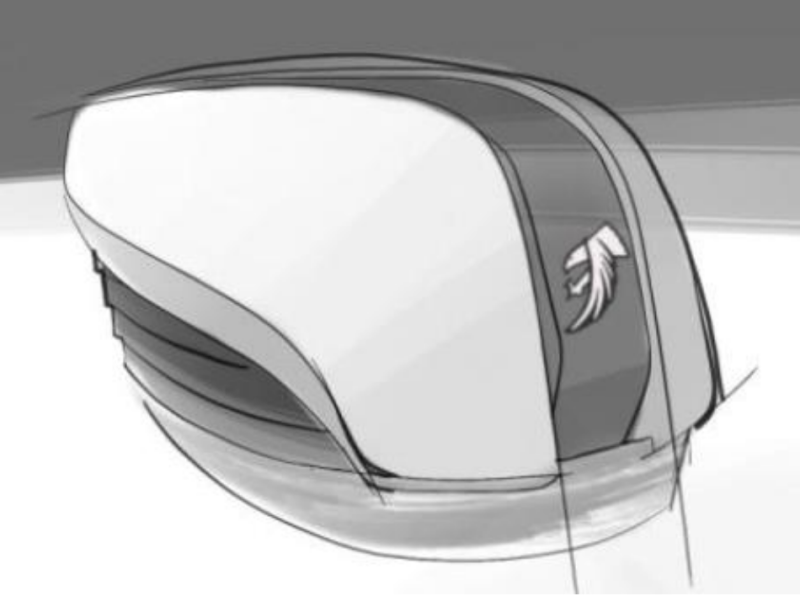

Development of outboard engine housing

| Project duration: | 01.05.2017 - 01.05.2018 |

As part of the project "Po kreativni poti do znanja", together with the students we constructed and designed the control lever of an outboard electric motor for boats.

Electric drives are increasingly replacing internal combustion engines in all areas. The aim of the project was to upgrade an outboard engine with a power of up to 15 kW so that it can be installed on smaller vessels. The company Podkrižnik d.o.o. is already available with the basic outboard motor construction. As part of the project, the base engine housing was reworked, upgraded with a control lever and a correspondingly reworked construction to make it universally applicable even on smaller boats. The outboard motor needs to shorten the leg and adjust the geometry of the propeller, so that the characteristics now correspond to the conditions of navigation in boats.

The project team worked in the planned structure (machinists, industrial designers and electrical engineers). At the headquarters of Podkrižnik d.o.o. we held an initial workshop where the work mentor and his colleagues presented the existing implementation of the outboard motor. Together, we divided the project into basic activities and made a project timeline. We divided the project into A) industrial design, B) constructing the crank and motor housing, C) electrical part. There was a constant need for coordination between the industrial design of the crank and the motor housing and the construction that ensures adequate sealing of the electric motor against water. An analysis was carried out of the suppliers of the marine propeller, which should also be suitable for the engine in question. On the basis of the collected material, the key parameters of the ship's propeller and their connection with the characteristics of the drive were determined. A new shaft design was made to attach a commercially available marine screw. The design also includes screw protection in the event that the screw jams. The industrial designers prepared in several steps proposals for the industrial design of the housing and control lever. They took into account the company's desire that the design be "sporty" with the company's own character. The designers analyzed the sealing options. They inspected the market and also visited the manufacturers of seals. A concept was created and then a construction was made for a functional prototype to test the seal. Based on the tests, the most suitable and robust silicone seal was selected. A 3D model of the motor housing was created with advanced surfaces and a new support plate with built-in seals. The results of industrial design and seal analysis were used in the new construction. The electrical team has compiled documentation for capturing data from the engine and battery and displaying the data. The control chain from the electric motor, the battery source, the controller to the display of the current values was placed in one place. A more powerful and functional user interface has been built into the control chain. Fulfilling the interdependent requirements for an attractive design, functional requirements for easy maintenance and reliable sealing, and technological feasibility is a complex task. Therefore, it was necessary to repeat individual steps several times. Finally, technical documentation was produced. This was followed by the creation of a prototype and final confirmation before the start of serial production.

Project Partners

Podkrižnik d.o.o.